Shock protection systems are different, but thanks to them, the watch was able to accompany a person in the most difficult circumstances.

From time immemorial, watchmakers have been trying to protect the heart of the clockwork from external influences, and first of all from sharp shocks. This is because the regulator, which divides time into separate moments with its oscillations, is both perfect and imperfect at the same time by its design.

Its perfection is expressed in the fact that the mass of the balance is concentrated on the periphery, due to which the balance wheel has significant inertia and oscillates evenly. But this is also the main disadvantage: this weight rests on a thin needle in the middle, the balance axis. So, if the watch suddenly experiences a serious blow, the balance axis does not cost anything to break - and the clockwork is finished.

Even Abraham-Louis Breguet tried to save the oscillator of a pocket watch with the help of a "parachute" - a special shock absorber for the balance axis. And the first modern system designed to take care of the regulator of wristwatches, whose whole life is continuous shocks, was Incabloc.

In each watch, the balance axis is inserted on both sides into stone supports, which are usually made of synthetic ruby. The creators of Incabloc placed springs under these supports so that the axle would not bend or break upon impact, but “jumping” along with the supports, it would calmly return to its place. Moreover, these shock absorbers allow the axle to move both horizontally and vertically.

Incabloc was developed by the Swiss company Porte-Echappement Universel in 1933, but gained wide popularity only in the 40s and 50s, Incabloc can still be found in the technical specifications of a huge number of modern watch models.

The shockproof Incabloc was developed by the Swiss company Porte-Echappement Universel in 1933, but the use of this system can still be found in the technical specifications of a huge number of modern watch models, for example, it is used in Perrelet Turbine watches.

The first anti-shock solutions

The history of automatic watches is believed to date back to 1770; then the watchmaker Abraham-Louis Perrelet created a watch that did not require daily winding. However, the problem of protecting the inertial sector became relevant only in the forties of the twentieth century, when automatic watches became widespread. The same applies to shockproof balance protection: it was seriously thought about only after the First World War, with the growing popularity of wristwatches (although the first steps in this direction were made by Breguet and his London partner Louis Recordon, who, by the way, like Breguet, was one He was one of the first to design self-winding watches).

On the first self-winding pocket watches, the freely rotating inertial sector, which is well known to any owner of a modern watch with a transparent back, as a rule, was absent. The watch in your pocket simply did not need a flywheel, a way to make a complete 360-degree rotation around its axis: it was enough for it to turn through a much smaller angle. Thus, the rotor oscillation sector had limiters on both sides, damping shock loads, which could not but be created by a swinging load.

In those days, such a buffer (by the way, winding systems of this type were also called “buffer ones”) invariably served as a spring. But the disadvantage of most buffer designs was that the swinging weight hit the spring directly, which caused it to wear and break.

How to fix it was invented by the Englishman John Harwood, who is considered the father of modern automatic watches. In 1924, Harwood filed a patent for a self-winding mechanism in which two spring-loaded stops were provided for the rotating weight sector, protecting the springs from direct impact from it.

BALL Watch's exclusive development, the SpringLOCK® anti-shock system, protects the balance spiral with a "cage" that limits the unwinding of the coils during sharp shocks from the outside. It significantly reduces the risk of cable breakage at the point of connection with the balance and the possibility of unexpected movements that can deform the cable.

Anti-shock systems in wristwatches

Today, different balance protection systems are used in watches: Incabloc, Kif-Flector, Etashok, Diashok (Seiko), Parashok (Citizen). In all these devices, we see the same way of attaching balance stones: they are mounted in a special tapered sleeve that ensures mobility, which watchmakers call a bushon.

The bouchon with applied and through stones is inserted into a correspondingly shaped socket made in a balance bridge or platinum. Thus, the axis of balance rests on four stones in two bushes, each of which is held in its seat by a spring. The conical shape of the bush allows it to move not only up, but also sideways. Moving, bushon dampens the impact energy, then under the influence of the spring returns to its original position. The main advantage of conical mount shock absorbers is that they not only protect the fragile tip of the axle from impact, but also self-center.

It took watchmakers a long time to learn how to securely protect fragile pins. But as soon as wristwatches appeared, much more vulnerable than pocket watches, shock absorbers of the balance axis began to be used almost everywhere. In 1937, watch companies produced almost one million watches with anti-shock systems, and by 1981, about seven hundred million such watches had already been produced. However, not all watches produced between 1937 and 1950 had shock protection.

However, everything changed after 1950, as soon as two obstacles to its wide distribution collapsed: firstly, the patent protection of the first generation of shock-absorbing devices expired, and secondly, high-end watch manufacturers finally realized that, contrary to initial fears, anti-shock systems do not impair the adjustment accuracy of their high-quality mechanisms.

In those years, the presence of a shock-absorbing device added considerable value to watches. Evidence of this is the inscription Anti-shock and Incabloc on the dials of old watches. Today, there are no such inscriptions, but this is also evidence of the ubiquity, relevance and effectiveness of modern anti-shock systems.

Graham 2CVCS.U14A.L129S

Incabloc Protects Graham Chronofighter Vintage Pulsometer Ltd from Breakage in the Event of an Impact

About Incaflex

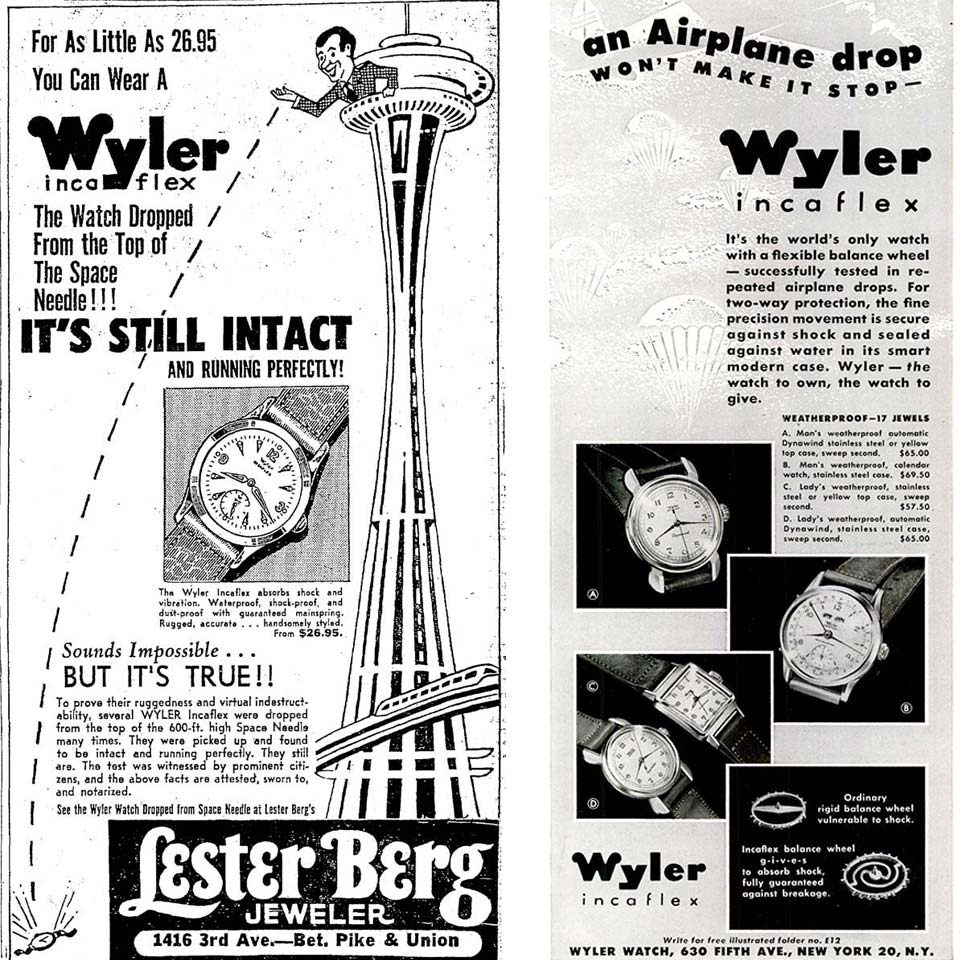

Today, a variety of solutions are used to protect balance pins. One of the curious non-standard options is a balance wheel with crossbars that slightly bend during bumps and bumps. Flexible crossbars protect the fragile axle, being, in fact, a mechanical "decoupling" between the trunnion and the main mass of the wheel. One of the most successful shockproof balance wheels was designed by Paul Wyler.

Incaflex - that was the name of the invention of Paul Wyler - was a balance wheel machined from a single piece of metal with two elastic semi-spiral crossbars symmetrically converging from the outer edge to the hub. Sensational tests were carried out to demonstrate the shock-absorbing properties of the new wheel. Two Incaflex watches were thrown from the Eiffel Tower in 1956. Then, in 1962, the test was repeated, dropping already six pieces from a 27-story skyscraper in the American city of Seattle. Needless to say, the clock continued to run properly even after such cruel treatment.

Marking "shockproof"

Nowadays, only those watches that are made in a country that has signed the protocol of the international standard ISO 1413-1984 (the equivalent Swiss standard is designated NIHS 91-10) are considered officially shockproof. These countries include Switzerland, France, Germany and Japan.

The standard describes the tests that certify watches for shock resistance. By the way, the designation “shockproof” is not provided by the standard; instead, the concept of “shock resistant” or its official equivalents in five languages should be used.

During the test, the watch case is struck with a special pendulum striker. The standard prescribes to apply two blows to each checked copy: one from the side of the dial, the other - from the side, near the 9 o'clock mark. The test is considered passed if the watch has not stopped and has not received any external damage. For mechanical watches, the accuracy of the movement is additionally checked: the deviation should not exceed 60 seconds per day.

The test procedure is extremely simple. The test bench is a table with a holder in which the watch is placed. Above the holder is a drummer on a pendulum suspension. The drummer is pulled up, then released. Upon impact, the watch flies off the holder towards the soft mat, which stops its flight. The watch is then checked for damage and deviations in accuracy.

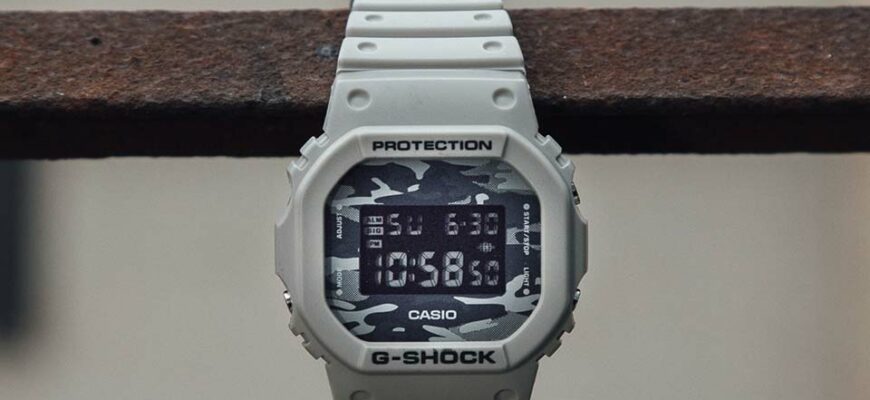

Any of hundreds of varieties of Casio G—Shock shock resistance is second to none: be it digital, digital-analogue, radio-controlled or solar-powered models with a microcomputer and tons of features.

G-Shock

Shockproof cases are very popular, providing protection not only for the balance axes, but for the entire mechanism as a whole. Their range is wide - from exotics like a titanium-niobium shell to a simple, but surprisingly effective multilayer composite case /watch/filter/brand:casio/collection:g_shock/G-Shock - the famous quartz watches produced by Casio.

The story of the invention of the G-Shock is sure to resonate with any watch aficionado: in 1981, engineer Casio Kikuo Ibe accidentally dropped his watch, a graduation gift from his parents, on a hard tiled floor and shattered it. As is often the case, tragedy became a source of inspiration. Kikuo Ibe set out to create a watch as invulnerable as modern science allows. By the way, this solemn promise led to one curiosity.

Kikuo Ibe's colleague Yuichi Masuda found it strange that he constantly visited the men's room on the second floor. Moreover, he spends no more than a couple of seconds there, after which he runs down to the parking lot behind the building. After inquiring, Masuda found out that Kikuo Ibe was experimenting with prototypes: throwing them out of the toilet window onto the pavement and watching how they take blows. It seems that G-Shock is the only one that can boast that it was tested for strength in such a non-trivial way. A special group was formed, the so-called "shock design team", but its members were not allowed to use the standard equipment from the Casio arsenal, since the program for creating a new model had no official status. So the role of the G-Shock test bed was assigned to the men's room.

How it all ended, we know. Any of the hundreds of varieties of G-Shock in shock resistance is unmatched, whether it's digital, digital-analogue, radio-controlled or models with solar panels, a microcomputer and a host of functions. In the very first version, DW-5000, all the security elements are already present, which later migrated to later models.

In particular, the watch is surrounded on all sides by an impressive hard urethane shell, which rises in the dial area, forming a barrier similar to those bone rollers that protect our eye sockets. So the high bezel protects such a vulnerable front side of the watch from all blows, except for very targeted ones. Although the GWM5600 A3, the modern descendant of the DW-5000's firstborn, has replaced the classic case with a screw-on back cover with a multi-layered shell, the G-Shock protection system still ensures compliance with the “rule of three dozen”: water resistance at a depth of 10 meters, impact resistance at 10m drop and at least 10 years of battery life.

The ultimate practicality of the G-Shock gives it a special charm and serves as its pass into the society of models that cost many orders of magnitude more expensive. In a world where a watch that can withstand a meter drop onto a hard wooden floor is considered "shockproof", and watch brands sing of this achievement as incredible, G-Shock is tasked with bringing dreamers down to earth. By the way, it is one of the four models officially selected by NASA for manned space flight. Do you really need after that some more proof of his driving performance and incomparable endurance?

Ball Watch's patented SpringSEAL system protects the redesigned regulator assembly, ensuring it doesn't change position upon impact

As you can see, the engineers-inventors of the past and our contemporaries are serious about protecting wristwatches from impacts and “shocks”, so that we always know exactly what time it is. Trust the professionals, don't test your watch for impact resistance, but rest assured that if something happens, it will withstand any (well, almost any) blow of fate.